The production of reflective fabric uses the principle of retro reflection. Reflective fabric is made of the base cloth, the adhesives, and the micro glass bead. And a variety of processing technology including coatings, composites, along with processing methods such as hot pressing is imperative. The micro glass bead for producing high and silver reflective fabrics are half coated with aluminum to improve the reflective coefficient significantly. The highly reflective glass beads coated in the surface of the cloth works by reflecting light back to the light source only, such as a car’s headlights. In other words, the reflective tape only lights up for the person with the light source or in line with it. This happens because the tape contains either glass beads or prisms that collect light, focus it and bounce it back to the source.

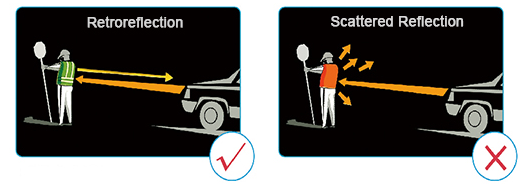

How does it do this? Imagine that you are in a round room and you are in the center of the room. If you throw a ball towards the wall it is always going to come back to you. Reflective fabric or reflective tape works in a similar manner. The diagram below shows how the glass beads or prisms do this.

Since very little light is scattered when the light is returned, retro reflective fabric or tapes appear brightest to an observer located near the original light source, therefore, it can help the eye perceive light in low-light conditions. Normally, man who wears clothes with reflective fabric on can be seen by drivers hundred meters away in darkness, which can surely avoid the occurrence of traffic accident.