Reflective heat transfer vinyl 101: What, Why and How to use Reflective HTV

"Chinastars has all kinds of reflective iron on vinyl to meet various customers' requirements and target different base fabrics such as spandex, flame-retardant, waterproof fabrics, etc.

We strongly believe that the extensive range of reflective heat transfer vinyl and iron-on reflective tape we supply will suit all of your transfer printing needs, whether they are for fashion, leisure, sports, or work wear."

What is reflective heat transfer vinyl?

Reflective heat transfer vinyl, or reflective HTV in short, is composed of a PET protective film liner, micro glass beads, and hot melt glue. It is a special vinyl polymer that can be used on certain fabrics and materials to create designs and promotional products. It comes in roll or sheet form with a plastic liner, allowing for easy cutting, weeding, and placement on a substrate for heat application. It is easy to use and provides both safety and customization options for all kinds of garments, shoes, caps, bags, and more.

How many different types of reflective HTV are there?

1. Grey/silver reflective HTV

2. Color reflective HTV

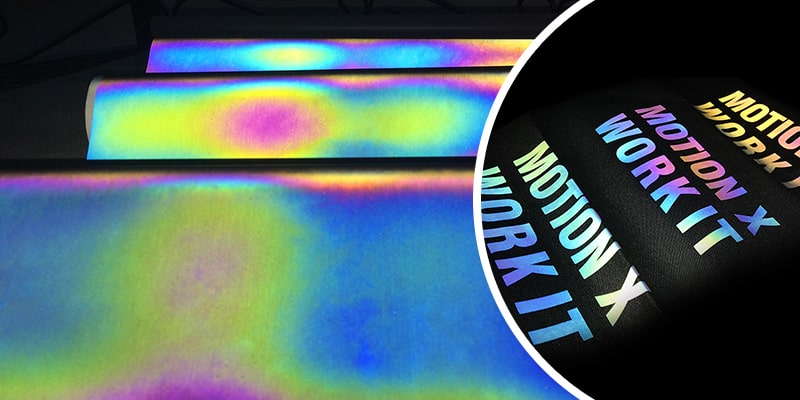

3. Rainbow reflective HTV

4. Printable Reflective HTV

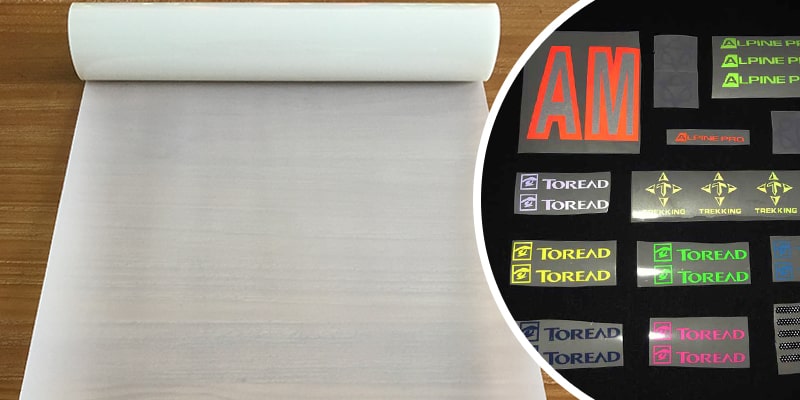

5. Customized Reflective Logo

6. Standard Iron-on Reflective Tape

7. Flame Retardant Reflective Heat Transfer Tape

8. Industrial Wash Iron on Reflective Tape

9. Segmented Iron-on Reflective Tape

10. Perforated reflective iron-on tape

Why use reflective heat transfer vinyl(HTV)?

Compared to the sew-on reflective material, Reflective heat transfer vinyl has the following advantages:

- 1. Seamless without stitching, allowing more comfort, and is skin-friendly.

- 2. More convenient and SAVE YOUR COST on waterproof garments: You have to use seam sealing tape on all stitching lines when using sew-on reflective material. But with reflective heat transfer vinyl and tape, no seam sealing is needed.

- 3. Reflective heat transfer material offers more possibilities for design purposes: You could create thousands of unique ideas to apply the reflection on your products, for example, your brand logos, segmented tapes, perforation, etc.

Compared to the normal heat transfer vinyl, a major benefit of using reflective heat transfer vinyl on clothes is that it helps enhance the visibility of the wearer in nighttime or low-light conditions when illuminated by a light source.

How do you choose reflective heat transfer vinyl?

As we know, reflective heat transfer vinyl (HTV) is widely used in t-shirts, sports equipment, and other fabric projects. However, its washing fastness is dependent on the backing fabrics and operation methods, not like the sewn-on reflective tapes. So, how do you choose high-quality reflective heat transfer vinyl?

Two factors are important, one is easy to use with plotter cutting and heat application, and the other is good quality for reflection and washing durability.

Chinastars' reflective HTV vinyl excels in both of the aforementioned aspects. Our team has innovatively developed a sticky base specifically designed for reflective heat transfer vinyl, which plays a crucial role in securely adhering the logo onto the material and ensuring ease of peeling. Additionally, during the heat transfer process, this sticky base effectively anchors the logo in the desired position on the fabric, guaranteeing precise and accurate application.

The reflection quality of Chinastars reflective heat transfer vinyl is certified by EN 20471, ANSI 107 standards, it could pass over 50 cycles of home washes if well applied on proper fabric.

For peace of mind, Chinastars' reflective HTV vinyl is also OEKO-TEX 100 certified to ensure it is free of harmful substances. Choose Chinastars Reflective HTV Vinyl for a high-quality, durable solution to all your reflective needs.

How to apply reflective heat transfer vinyl (HTV)?

The steps for applying a reflective heat transfer vinyl onto a garment are as follows:

- Step 1. Remove the adhesive side liner, exposing the dry adhesive. Do not remove the reflective side liner.

- Step 2. Place the heat transfer film on the fabric with the adhesive side down and apply heat and pressure as described below.

- Step 3. Allow the heat transfer film to cool to room temperature. Remove the reflective liner by lifting one corner and pulling (180° angle) in a continuous, smooth manner.

How long do you press reflective heat transfer vinyl?

The different types of heat transfer reflective vinyl require different operation methods, such as temperature, line pressure, and dwell time. Before buying the heat transfer reflective vinyl, check the fabric condition and application of the products, then choose the suitable quality reflective heat transfer tape. In this way, our sales team can recommend and give you the detailed suggested operational methods. It would be great if you could send the backing fabric to our test lab to do the washing test.

Below is a table of recommended iron conditions for each vinyl and machine. Alternatively, feel free to contact us by email at info@chinastars.com.cn, and we'd be happy to discuss your needs and give you our advice.

| Products | Applications | Heat Press Machine | Heated Roll Laminator | ||||

|---|---|---|---|---|---|---|---|

| Temperature | Dwell Time | Line Pressure | Temperature | Rotate Speed | Line Pressure | ||

| Grey reflective heat transfer film CSR-4002 | Non-stretchable ordinary fabric, such as polyester taffeta | 140-160℃ | 8-20s | >0.5kg/cm² | 120-140℃ | 4-8m/min | 4kg/cm² |

| Silver reflective heat transfer film CSR-4003 | |||||||

| Color-reflective heat transfer film | |||||||

| Rainbow reflective heat transfer film XC8003-A | |||||||

| Segmented reflective heat transfer tape CSR-4003-Z*** | |||||||

| Grey reflective heat transfer film for graphic design CSR-4002T | Specially made for graphic design for non-stretchable ordinary fabric | ||||||

| Silver reflective heat transfer film for graphic design CSR-4003D | |||||||

| Silver reflective heat transfer film with adhesive protective film CSR-4003-M | |||||||

| Stretchable silver reflective heat transfer film CSR-4003E | Stretchable fabric such as spandex, birdeyes, elastic band, etc. | 150-170℃ | 10-20s | >0.5kg/cm² | 120-140℃ | 4-8m/min | 4kg/cm² |

| Silver stretchable reflective heat transfer film with adhesive protective film CSR-4003E-M | Specially made for graphic design for stretchable ordinary fabric | ||||||

| Flame-retardant silver reflective heat transfer film CSR-4003FR | Flame-retardant fabric | 160-180℃ | 10-20s | >0.5kg/cm² | 130-150℃ | 4-8m/min | 4kg/cm² |

| Industrial wash silver reflective heat transfer film CSR6670 | Fabric requires industrial wash | 160-180℃ | 10-20s | >0.5kg/cm² | 150-180℃ | 4-8m/min | 5kg/cm² |

| Water-repellent silver reflective heat transfer film CSR-4011 | Water-repellent fabric, such as waterproof-treated Oxford | 100-160℃ | 12-60s | >0.5kg/cm² | 120-140℃ | 4-8m/min | 4kg/cm² |

| Silver stretchable segmented transfer film CSR-4003E-Z*** | Stretchable fabric such as spandex, birdeyes, elastic band, etc. | 140-160℃ | 8-20s | >0.5kg/cm² | 130-150℃ | 4-8m/min | >2kg/cm² |

| Industrial wash segmented transfer film CSR6670-Z*** | Fabric requires industrial wash | 160-200℃ | 10-20s | >0.5kg/cm² | 130-180℃ | 3-8m/min | >2kg/cm² |

Why buy reflective heat transfer vinyl from Chinastars?

-

1. Decades of Experience

Chinastars is a marketing-influential manufacturer of reflective heat transfer vinyl with over 19 years of experience. We are also a public company with the China Stock Exchange (Stock code: 301077).

-

2. Quality Control

We prize high-quality work and hold ourselves to higher standards. Our offered products are manufactured by international standards using qualitative raw materials sourced from the famed vendors of the market. Our reflective HTV is certified to EN 20471, ANSI107. FR reflective heat transfer tape is UL-certified for NFPA2112, EN469, and EN20471.

-

3. Service

Chinastars deem excellent services as important as extraordinary quality. Decades of experience enable us to provide comprehensive services to our customers. We put our customers' needs above all else and serve every customer with strong business ethics and integrity. We do what we say we will do. If you have any problems, feel free to contact us by email at info@chinastars.com.cn.

Additional questions that we're commonly asked

-

1. How to choose appropriate heat transfer vinyl for my fabric? Is a free sample available?

Yes. Our company can provide free samples for testing. If possible, we'd highly suggest customers send the target fabric to our factory. Our technical person will try different heat transfer vinyl on the fabric and do a washing test. After that, we'll recommend the appropriate heat transfer vinyl with heat conditions and send samples to you for testing.

-

2. Will you guide us on how to heat-press your heat transfer tape?

Yes. We'll send you the operation guide, handling precautions, and reason analysis for frequently occurring problems. In case of any questions during your sample testing, we'll ask our technical person to analyze and send you the solution report. We'll do everything to make sure you get the best heat condition before mass production.

-

3. How many kinds of reflective heat transfer film do you have altogether?

We have reflective iron on vinyl targeting different base fabrics such as non-stretchable, stretchable, flame-retardant, water repellent, industrial wash, or PU materials, etc. We also have heat transfer vinyl specially made for engraving or laser cutting, and multiple-segmented reflective heat press vinyl.

-

4. Can we order reflective heat transfer logos? Is a free sample available?

Yes. We can customize reflective logos according to your artwork. We can provide several pieces of free samples for your reference.

-

5. What's the MOQ of the reflective heat transfer logo?

We don't have a specific MOQ for reflective logos. We can accept small quantity orders as well.

-

6. Can we customize different shapes of segmented heat transfer reflective vinyl?

Yes. We can make molds according to your artwork and then do mass production.

-

7. Are all reflective heat transfer vinyls in stock?

Some regular products are in stock, but we always ask you to confirm through the inquiry system before making the purchase.

-

8. How to get samples or request a quote?

To request a sample or obtain a quote, please get in touch with Chinastars: Email: info@chinastars.com.cn Website: www.chinareflective.com You can leave a message on our website or send your request via email. We will have a dedicated sales representative reach out to assist you with your needs.

-

9. Why choose Chinastars reflective HTV?

20+ years of experience in reflective materials;

Comprehensive product portfolio: HTV, tapes, fabrics, yarns;

Certifications: OEKO-TEX 100, GRS, ISO 9001, ISO 14001; EN 20471, ANSI 107,etc;

Global reach: Serves 100+ countries;

Customer support: Samples, technical guides, videos;

Sustainable production: Eco-friendly coatings and recyclable components

Some suggestions for extending the life of reflective heat transfer vinyl:

- 1. Use neutral detergent in hand washing. Do not use a detergent that contains bleach, acid, or alkali.

- 2. When doing machine washing, you may use a mild detergent, but No Bleach or Fabric Softener!

- 3. Avoid washing the reflective products with your work jeans or any clothing with rough fabric or edges. The microscopic glass beads on the reflective fabric can be worn off by the rough texture.

Handling precautions

Reflective HTV contains an aluminum layer, and sweat/oil/water stains may occur if the surface of the product has direct contact with hands during application and is then exposed to hot and humid conditions. Even though these blemishes won't affect the performance of the product, we strongly recommend handling the reflective fabric with gloves and keeping it in an environment of below 26.7 °C (80 °F) and lower than 70% relative humidity.

Reflective HTV Storage and shelf time

Store in a cool, dry place and use within one year after the date of receipt.